What makes Leys so unique

At Leys, we combine a passion for technology and mechanics with expertise in turning, milling and optimization. Thanks to our fully in-house process – from design and strength calculations to production – we offer solutions from A to Z. This makes Leys the ideal partner for downtime or critical work.

- Quick response to downtime

- We understand that downtime costs money. Thanks to our short communication lines and efficient work structure, we can respond quickly and plan interventions.

- Flexibility through extensive machinery

- With a diverse and modern machine park, we are able to deliver custom work, even for complex or urgent assignments.

- Short lead times

- Thanks to our internal processes and extensive material stock, we minimize waiting times and guarantee fast delivery.

- Proactive and reactive investigation in case of machine breakdown

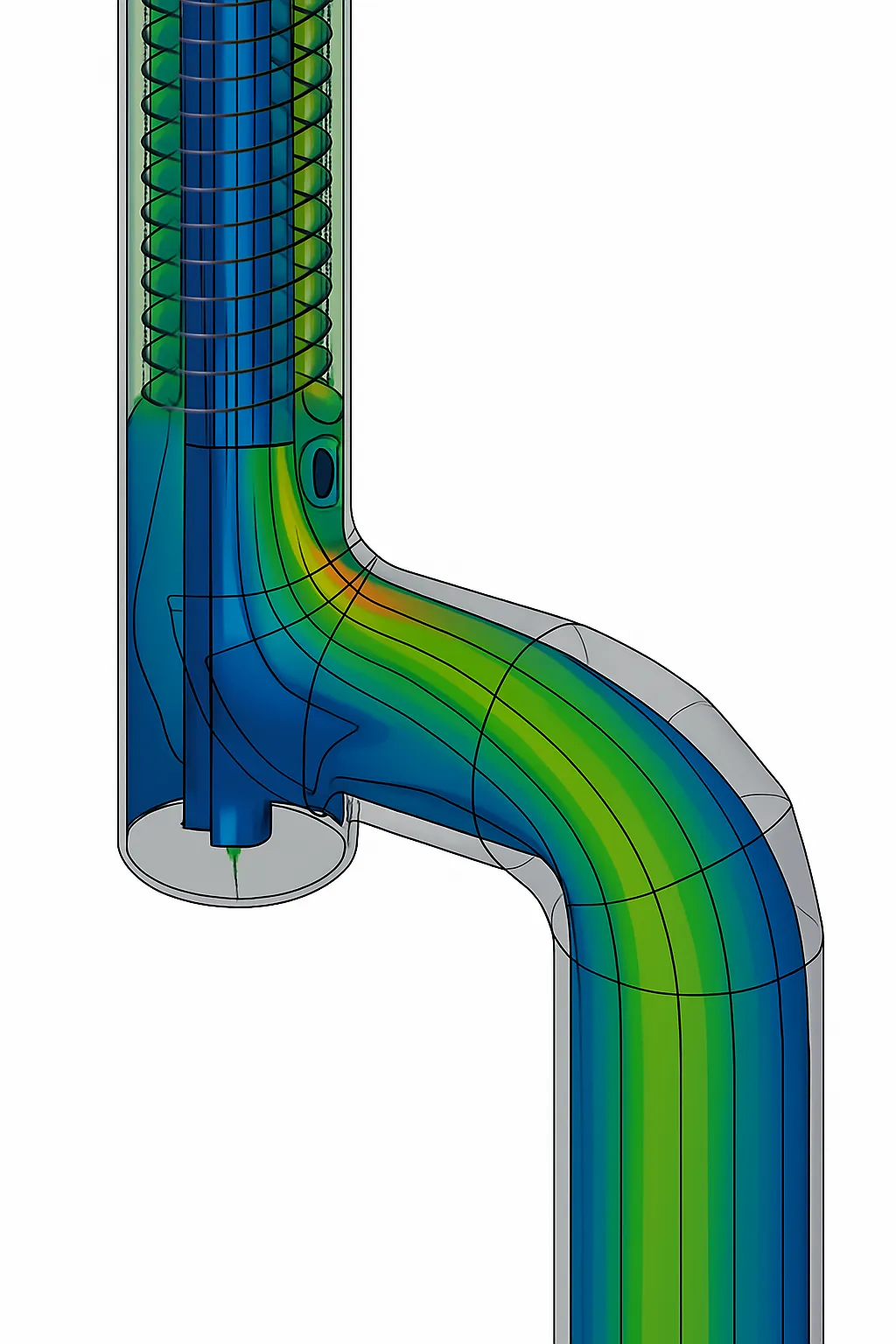

- We perform thorough analyses via FEA and CFD to detect problems and prevent future defects.

Factory as a Service (FaaS)

Factory as a Service (FaaS), 'powered by' NEXXURA and Leys NV. By joining our forces, you benefit from lower fixed costs, faster time-to-market, high flexibility, reduced risk management, high quality, and predictability.

- Lower fixed costs (CAPEX)

- No large investments in your own factories or machines.

- Faster time-to-market

- Our workflows enable us to produce parts efficiently so that customers can assemble and deliver within days or weeks.

- Flexibility & risk management

- You can easily adjust designs.

- High quality & predictability

- Standardized, measurable processes ensure consistent, reliable results.

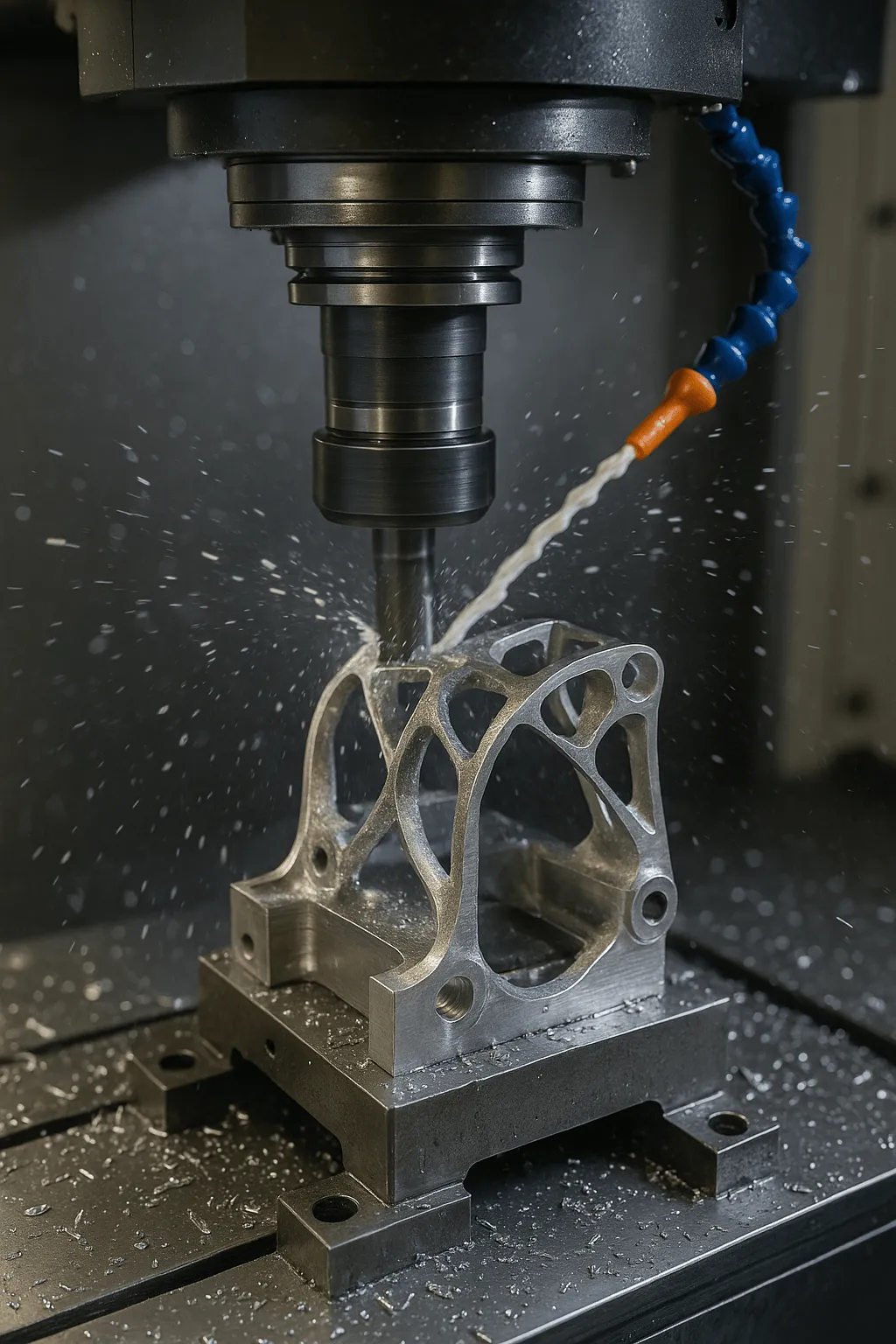

Milling

Thanks to our advanced machine park with various vertical centers and 5-axis machining centers, we at Leys can machine workpieces up to 4500 × 2500 × 1600 mm and weighing up to 5 tons with IT6 accuracy, enabling us to deliver both simple and complex customized solutions of high quality.

Turning

With IT6 accuracy, we machine workpieces with a diameter up to Ø1300 mm, a Z-axis length of 5000 mm, and a weight up to 4 tons, guaranteeing craftsmanship and quality for both precision work and larger projects.

Welding

Leys delivers high-quality welded constructions, from simple to complex projects, with expertise in MIG and TIG welding for a wide range of applications and materials such as steel and stainless steel.

Plastic Production

Leys offers a complete solution for plastic production, with 3D printing (FFF, SLA, SLM) and injection molding of small to medium series in various thermoplastics (ABS, PP, PE, TPE), ensuring the right technology is always applied.

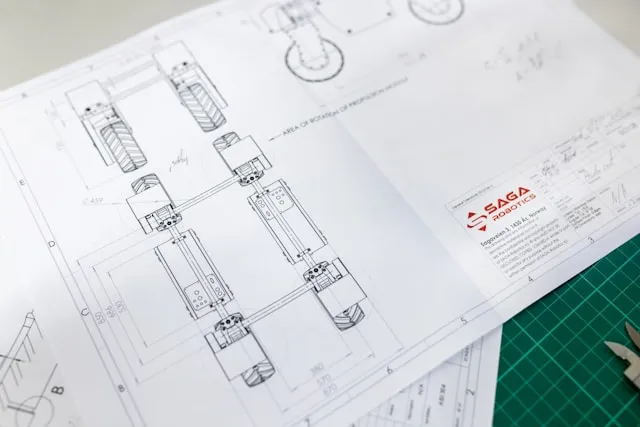

Engineering

With decades of experience in design and engineering and hands-on expertise across all industries, our passionate team delivers innovative custom solutions for the most complex challenges.

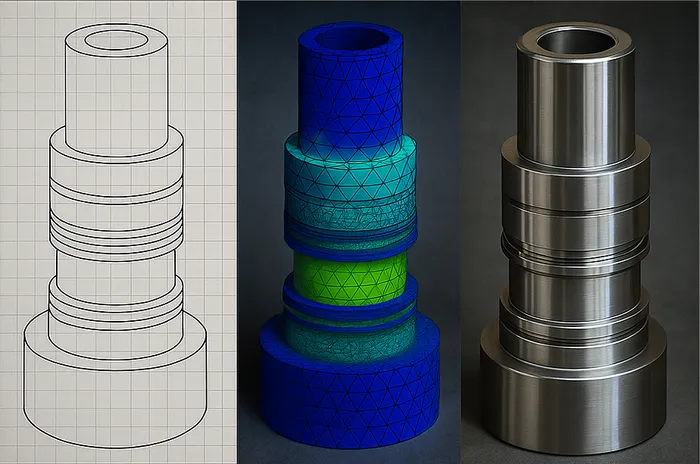

Finite Element Analysis

At Nexxura, we have a passion for FEA (Finite Element Analysis). Strength calculations on mechanical structures are part of our core business.

Computational Fluid Dynamics

Led by a hands-on specialist, we continuously search for realistic and applicable solutions.

Prototyping

We offer a complete total solution that minimizes lead times and guarantees both quality and speed.

Our History

A journey of craftsmanship and innovation, from a humble beginning to a future-oriented enterprise.

Leys NV

Founded as a sole proprietorship, with a focus on local craftsmanship.

Relocation to the new facility

Leys is expanding and relocating to the Industriezone Zuid-III in Erembodegem.

ISO 9001 Certification

An important milestone confirming our commitment to quality and standardized processes.

Cooperation with NEXXURA

Stronger together, with a shared focus on innovation and quality for the future.

What makes Leys unique?

At Leys, we combine a passion for technology and mechanics with in-depth expertise in engineering and production.

- Your Partner: From Engineering to Fabrication

-

Leys offers a complete trajectory from concept, engineering and prototyping to process optimization. Everything under one roof for maximum efficiency.

- Seamless Integration of Design and Production

-

Our engineers and production specialists work closely together. This guarantees manufacturable designs and a flawless trajectory from idea to final product.

- Unique Expertise in Diverse Materials

-

Benefit from our broad material expertise in both metal and plastic for the best and most sustainable solution.

- Driven by Optimization and Prototyping

-

Leys excels in fast, iterative optimization. Validated concepts result in 'first time right' prototypes.

- Efficiency in Production and Cost Savings

-

We proactively think along to analyze and improve your products for higher returns and lower costs.

- Innovative Custom Solutions

-

Thanks to our unique combination of comprehensive knowledge and production techniques, we develop creative custom solutions.

Get in Touch

Do you have a question or a project idea? We're happy to help.

- Bedrijfsnaam

- Leys

- Address

- Industrielaan 30

9320 Erembodegem - info@leys.be

- Phone

- +32 53 64 72 72